What are the different types of laser marking technology?

Laser marking is a versatile technology used to create permanent markings on a wide range of materials. However, it is not a one-size-fits-all process. There are several distinct types of laser marking, each with its own unique characteristics, applications, and advantages. Understanding the different types of laser marking is essential for selecting the method best suited to your specific needs.

- Laser engraving

This technology uses a laser beam to remove material from the surface, creating cavities that form permanent, tactile 3D markings. Suitable for various materials including metal, plastic, wood, glass, and ceramics, it is widely used for serial numbers, logos, and decorative designs.

Additionally, laser engraving offers high precision and durability, making it ideal for applications requiring detailed and long-lasting markings, such as industrial components, electronic devices, and promotional products.

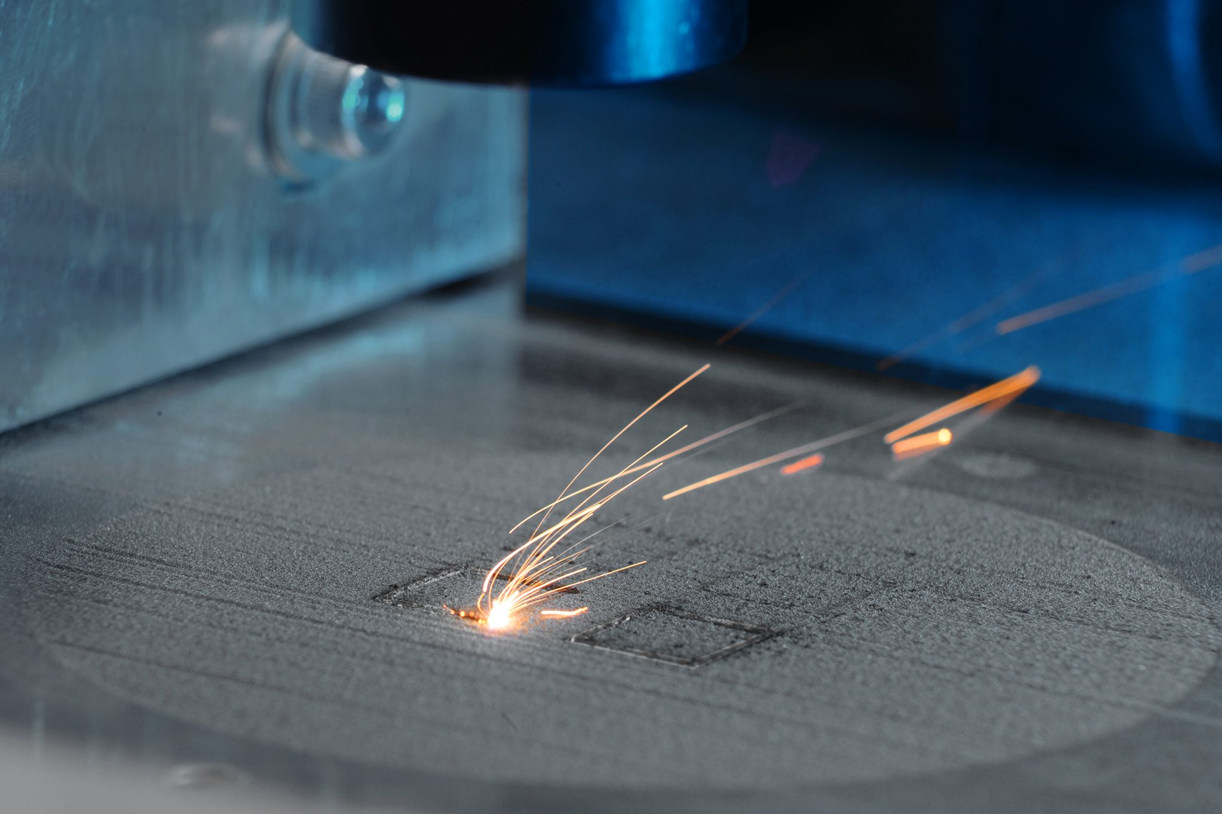

Laser etching

Laser etching involves melting the surface of a material with a laser beam, which then solidifies to form raised markings. It is highly suitable for high-contrast marking on metal surfaces and is commonly used for barcodes, QR codes, and data matrix codes.

Laser Etching Examples

Additionally, laser etching is less invasive than engraving because it only affects the surface layer of the material. This makes it suitable for thin or delicate materials that could be damaged by deeper engraving. It is commonly used in the electronics, automotive, and medical industries to mark components with serial numbers, part numbers, and other identification codes.

Laser annealing

Laser annealing involves heating the surface of a material with a laser beam, causing a color change without removing any material. It is suitable for metals such as stainless steel and titanium that undergo color changes when heated, and is commonly used for logos, text, and decorative designs.

This process is particularly useful for medical devices and surgical instruments because it does not remove any material or create crevices where bacteria could accumulate. Additionally, it produces smooth, corrosion-resistant surfaces that are ideal for applications requiring both aesthetic appeal and functional durability.

Laser Carbon Migration

Laser carbon transfer is a technique that uses a laser beam to heat the surface of a material, causing carbon particles to migrate to the surface and form a dark mark. It is suitable for metals with high carbon content, such as steel and iron, and is commonly used for serial numbers, text, and logos.

The process produces a deep, dark, permanent mark that is resistant to wear and corrosion, making it ideal for applications requiring durable marking, such as industrial components, tools, and equipment.

- Laser foaming

Laser foaming involves using a laser beam to melt the material surface, forming a foam-like structure that creates raised textured markings. It is suitable for certain plastics that produce gas when melted and is commonly used for barcodes, logos, and text.

The resulting markings are highly visible and durable, making them ideal for applications requiring high-contrast markings, such as consumer goods, automotive components, and electronic devices.