Research and Application of Laser Composite Cleaning Technology for Paint Removal

1. Introduction

Laser cleaning technology emerged in the mid-1980s but only entered industrial production in the early 1990s. It is now widely applied in mold cleaning, material surface treatment, and paint/rust removal from large equipment and precision machinery. Laser cleaning offers advantages such as simple operation, environmental friendliness, non-damaging effects on substrates, and broad material applicability. It fully aligns with the “green and eco-friendly” processing philosophy, establishing itself as a reliable and effective cleaning method. In recent years, growing emphasis on environmental sustainability coupled with declining costs of lasers and associated hardware has broadened the application scope of laser cleaning, propelling the industry into a period of rapid development. However, compared to traditional sandblasting and grinding techniques, laser cleaning exhibits low efficiency and slow speed when removing thick paint layers, failing to meet the productivity demands of modern manufacturing enterprises. Laser hybrid cleaning creates a novel cleaning mechanism through the interaction of continuous and pulsed lasers. Continuous laser irradiation of the substrate surface causes the paint to absorb the laser energy. Some paint directly absorbs heat and vaporizes, while other paint absorbs heat and expands, reducing the bond strength between the paint and the substrate. The continuous laser preheats the surface paint, enhancing its absorption rate. Consequently, when the pulsed laser irradiates the substrate surface at shorter intervals, the surface paint vaporizes more readily. Simultaneously, the high-frequency characteristics of the pulsed laser generate vibrational shock waves, accelerating the detachment of the weakened paint layer. This achieves rapid removal of surface paint deposits. To overcome the limitations of single-laser cleaning and enhance paint removal efficiency, this study employs a hybrid cleaning system and a high-power 1000W pulsed laser cleaning system. It explores optimal process parameters for laser hybrid cleaning, compares the efficiency and effectiveness of 1000W pulsed laser cleaning alone, and provides reference for expanding the laser cleaning application market.

2. Experimental Methods and Equipment

The test materials comprised 300mm×300mm plain carbon steel plates and 300mm×φ50mm gear-shaped suspension rods. The carbon steel plates were coated with approximately 100μm of epoxy anti-rust paint, while the gear-shaped rods were coated with approximately 150μm of epoxy resin paint. A laser hybrid cleaning method was employed, utilizing unidirectional robotic arm movement combined with oscillating galvo mirrors. This approach investigated the effects of different field lenses (F160/F255), scanning speeds, defocusing amounts, and movement speeds on cleaning efficacy and efficiency. The efficiency and effectiveness of high-power continuous + pulsed laser hybrid cleaning were compared with those of single-pulse 1000W laser cleaning for paint removal.

3. Experimental Results and Analysis

3.1 Scanning Tests with Laser Composite System Galvo Mirror

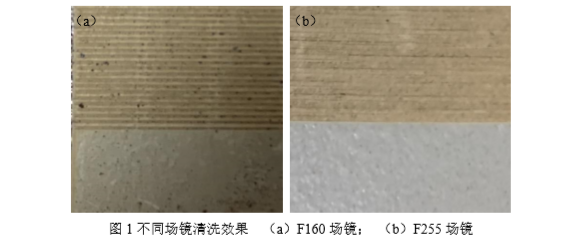

3.1.1 Comparison Test with Different Field Lenses

When cleaning 100μm-thick epoxy anti-rust paint, Figure 1 shows that the F160 field lens produced a vertical stripe pattern with large spacing and significant paint residue. The F255 field lens produced minor vertical striations with narrower spacing and partial paint residue. Compared to the F160 field lens, the F255 field lens delivered a larger focused spot size, enabling a broader single-pass cleaning area. This resulted in narrower striation spacing, a relatively uniform surface finish, and reduced substrate damage. Subsequent experiments were validated using the 160mm field lens.

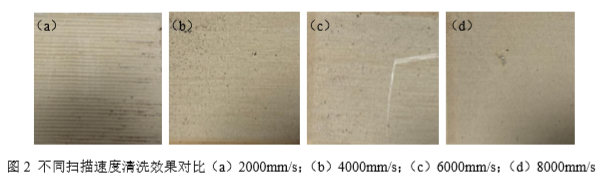

3.1.2 Comparative Testing of Different Scanning Speeds

By adjusting process parameters to achieve identical cleaning efficiency, the cleaning effect of varying scanning speeds on 100μm-thick epoxy anti-rust paint was evaluated. Analysis of Figure 2 reveals that at a scanning speed of 2000mm/s, the cleaned surface exhibits striped patterns with larger spacing. At 4000mm/s, the cleaned surface also shows striped patterns but with narrower spacing. At 6000 mm/s, the surface exhibited minimal striations. At 8000 mm/s, the outer surface appeared smooth. Faster scanning speeds resulted in fewer cleaning striations and more uniform cleaning. However, considering that excessively high galvo scanner speeds compromise stability, the scanning speed should be set to 8000 mm/s.

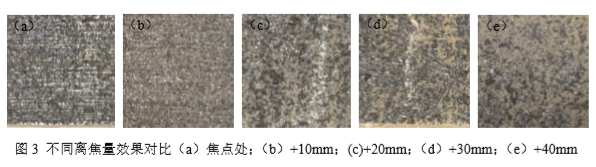

3.1.3 Comparison Test of Different Defocus Amounts

When cleaning 100μm-thick epoxy anti-rust paint, analysis of Figure 3 shows that cleaning at the focal point and positive defocus +10mm can completely remove the paint but causes surface damage, leaving stripes on the metal surface after cleaning. Cleaning at positive defocus values above +20 mm avoids surface damage but fails to remove all paint. Cleaning efficacy decreases with increasing defocus. Therefore, setting defocus between +20 mm and +30 mm achieves adequate cleaning performance without causing surface damage.

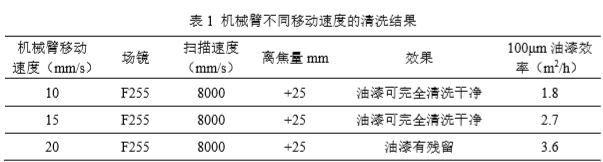

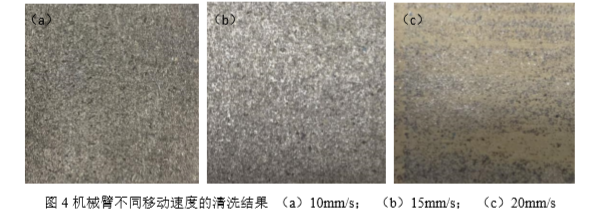

3.2 Flight Test of Laser Hybrid System Robotic Arm

Cleaning of 100μm-thick epoxy anti-rust paint revealed through Table 1 and Figure 4 that faster robotic arm speeds reduce single-pass cleaning efficiency, while slower speeds increase substrate damage and promote oxidation-induced blackening. Therefore, different movement speeds must be matched to different paint thicknesses. For 100μm-thick gray epoxy anti-rust paint, the optimal robotic arm movement speed is approximately 15mm/s. After cleaning, no paint residue remains on the surface, and the substrate exhibits a metallic bright white appearance.

3.3 Comparison of Laser Hybrid Cleaning and 1000W Pulsed Laser Cleaning

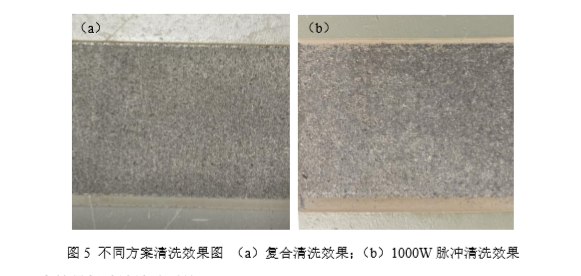

3.3.1 Comparison of 100μm Paint Removal

Experiments were conducted using both the composite cleaning system and the pulsed 1000W laser cleaning system on 100μm-thick epoxy anti-rust paint. Analysis of the results in Figure 5 shows that for relatively rough surfaces, both laser composite cleaning and 1000W pulsed laser cleaning can thoroughly remove surface paint without damaging the substrate, with both methods meeting the cleaning requirements for surface appearance. The composite cleaning system achieved an efficiency of 2.7 m²/h, while the 1000W pulsed laser system reached 3.6 m²/h. The cleaning efficiency of the 1000W pulsed laser was slightly higher than that of the combined continuous + pulsed laser composite system.

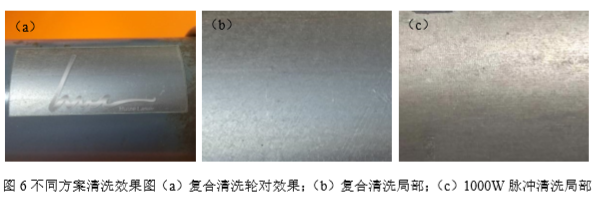

3.3.2 Comparison of Paint Removal on Gear Boom

Analysis of Figure 6 indicates that both laser hybrid cleaning and 1000W pulsed laser can effectively remove paint from the gear boom surface. Comparing Figures 6b and 6c reveals that the hybrid cleaning system achieves a paint removal rate of 3.24 m²/h for 150μm paint layers. The cleaned surface appears smooth with no cleaning streaks, exhibiting the bright white metallic substrate color. The 1000W pulsed laser achieved a cleaning efficiency of 4.2 m²/h for 150 μm paint, leaving slight traces on the surface with a yellowish tint. Reducing the power enabled damage-free cleaning at an efficiency of 1.7 m²/h, significantly lower than the composite cleaning system's 3.24 m²/h. This demonstrates that the composite cleaning system offers distinct advantages when cleaning smooth components like bearings, enabling damage-free cleaning at a high efficiency.

4. Conclusion

Through process debugging and optimization, laser-paint composite cleaning can be achieved. This method utilizes continuous lasers to ablate thick surface paint layers while preheating underlying thin paint layers. Subsequently, pulsed lasers clean residual thin paint layers beneath, effectively enhancing cleaning efficiency while ensuring surface cleaning quality. Compared to using a standalone 1000W high-power pulsed laser cleaning system, laser composite cleaning offers significant cost savings. It demonstrates particular advantages for cleaning smooth components like bearings, enabling non-destructive cleaning with higher efficiency. This technology holds promising application prospects in rail transit and marine industries.