Laser Cleaning: Four Common Methods

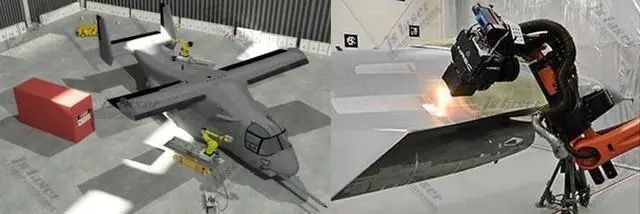

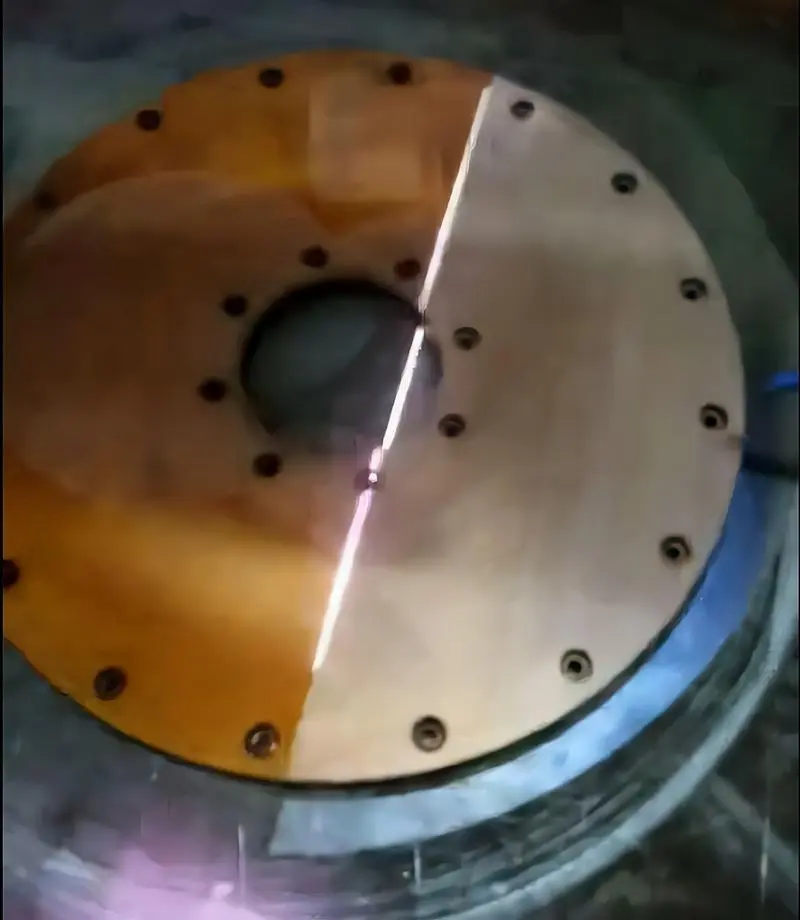

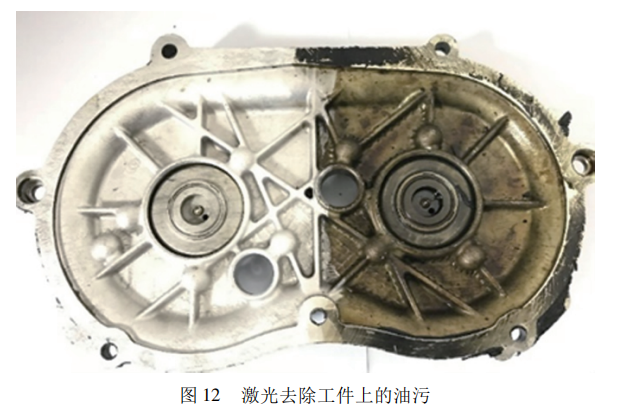

Principle of Laser Cleaning: This method employs high-frequency, high-energy laser pulses to irradiate the workpiece surface. The coating layer instantly absorbs the focused laser energy, causing surface contaminants such as oil, rust spots, or coatings to vaporize or peel off in an instant. This achieves rapid and effective removal of surface deposits or coatings. Under appropriate parameters, the extremely short duration of the laser pulses prevents damage to the underlying metal substrate.

Four Common Laser Cleaning Methods:

1. Laser Dry Cleaning: Directly irradiating contaminants with pulsed laser beams to remove them;

2. Laser + Liquid Film Method: First depositing a liquid film layer on the substrate surface, then using laser irradiation to clean contaminants;

3. Laser + Inert Gas Method: Simultaneously directing inert gas toward the substrate surface during laser irradiation. Contaminants detached from the surface are immediately blown away by the gas to prevent recontamination and oxidation;

4. Laser-Assisted Chemical Cleaning: Using laser irradiation to loosen contaminants, followed by non-corrosive chemical cleaning.

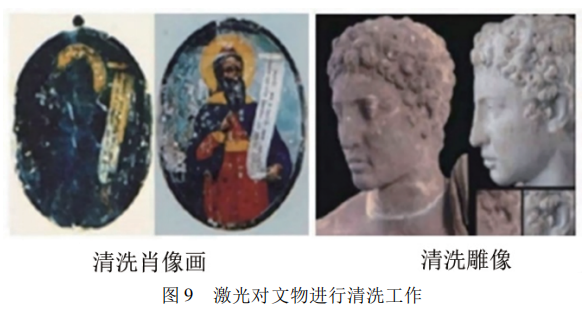

The first three methods are the most commonly used. The fourth method is only seen in the cleaning of stone artifacts. Internationally, laser cleaning technology has been applied to stone materials for over a decade. In China, laser cleaning of stone materials began relatively late. Due to the relatively high investment cost of laser equipment, widespread adoption remains challenging. However, laser cleaning technology offers unparalleled advantages over traditional methods. With continuous technological refinement and mass production of equipment, laser cleaning is poised to play a significant role in the stone cleaning industry.

Top Optics Laser's independently developed next-generation handheld laser cleaner features an integrated structural design, offering optional MOPA pulsed or flat-top pulsed fiber lasers; Pre-installed with a multifunctional laser cleaning control system, it seamlessly integrates with automated processing systems across industries. Equipped with an elastic weight reducer, it allows for free directional adjustment, reduces operational weight, and makes cleaning more effortless. Classic applications include laser cleaning of oxide layers and stainless steel. The laser cleaning machine can remove rust, paint, and more. Below are cleaning effect comparisons and detailed views of the cleaning machine:

For information on laser marking machines, laser welding machines, and laser cutting machines, please visit the official website of Tor Laser: http://www.tollaser.com