How to Maintain the Cutting Efficiency of a Laser Cutting Machine?

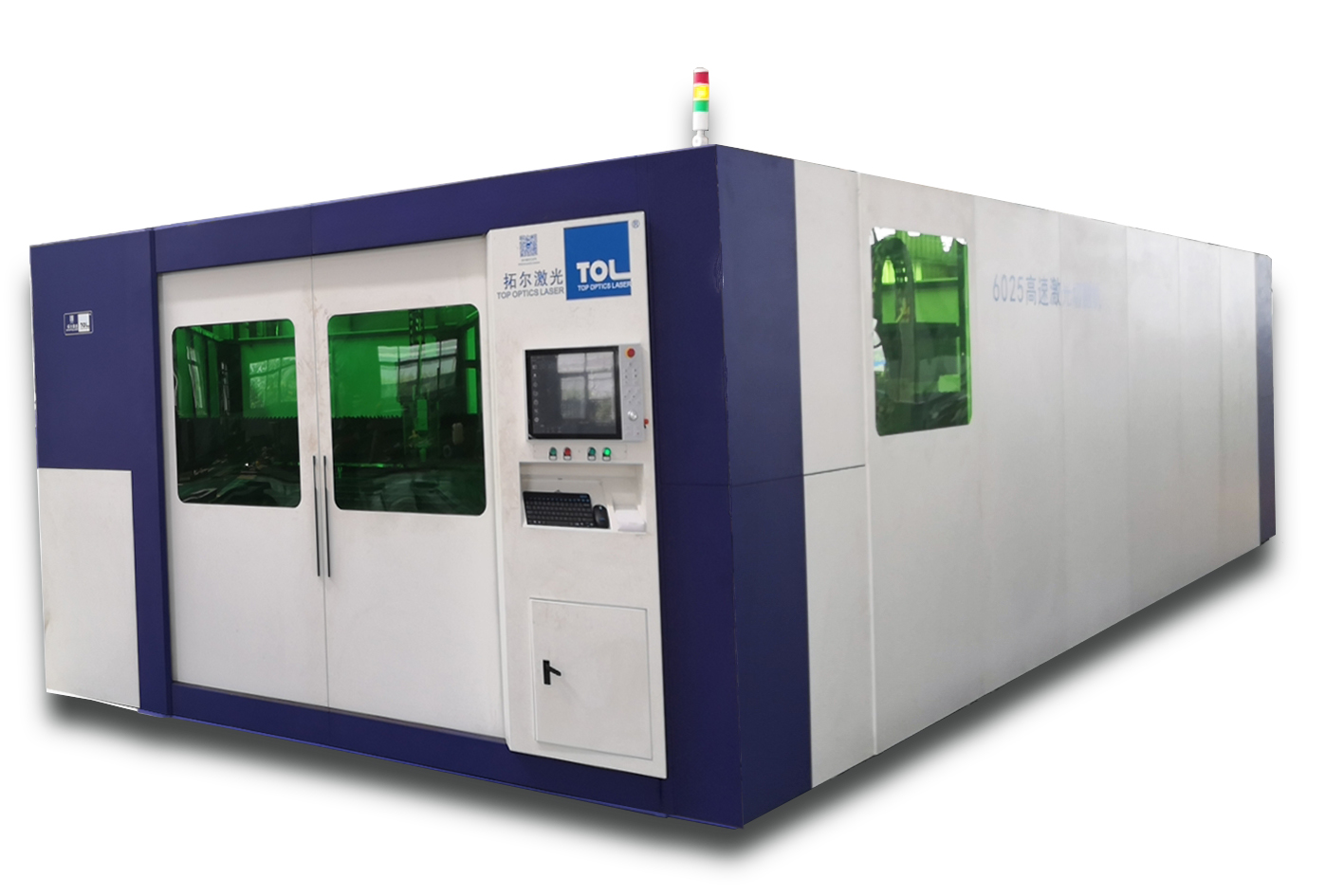

Compared to traditional cutting machines, laser cutters offer high efficiency, precision, and low pollution. Moreover, laser cutters can swiftly and accurately cut various materials like metals. Therefore, maintaining the machine's high cutting efficiency is crucial. Below are several key points to note when operating the equipment.

I. Cutting Layout Planning

When performing laser cutting, first carefully examine the blueprint. Then, based on the blueprint, plan the entire cutting path. The priority is to ensure the cutting quality of the workpiece while minimizing the cutting route to avoid redundant cuts.

II. Debugging Laser Cutting Machine Parameters

Setting the laser cutting machine parameters is a critical step and one of the key factors affecting cutting speed. Improper parameter adjustments will impact cutting speed. Depending on the shape and material of the workpiece, the cutting parameters must be set and modified accordingly.

III. Cutting Machine Operating Environment

If the laser cutting machine operates in temperatures exceeding 30°C or below 18°C, especially in humid or dusty conditions, it significantly increases the risk of machine malfunctions and severe damage. Therefore, strict attention must be paid to the cutting machine's working environment.

IV. Scheduled Maintenance

After a period of use, laser cutting machines require calibration and maintenance. While laser equipment consists of numerous components, some parts have relatively short maintenance intervals and are easy to service. Regular upkeep is necessary to ensure the laser cutting machine operates normally and efficiently.