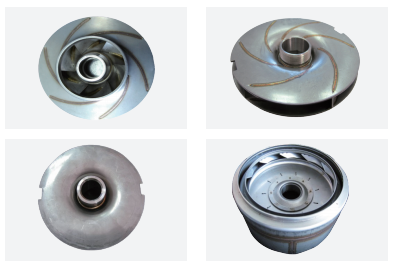

Application of Laser Welding Machines in the Water Pump Industry

Stainless steel impellers are critical components of water pumps, with their dimensions and precision directly impacting the pump's hydraulic performance. Closed impellers, in particular, are widely used in high-efficiency centrifugal pumps due to their high efficiency characteristics. Laser welding offers advantages such as superior weld quality, deep penetration, robust joints, low heat input (resulting in minimal workpiece deformation), high welding efficiency, and suitability for automated production. Practical high-power laser welding machines for pump impellers, with their superior performance and excellent practicality, are poised to become a dominant trend in the pump industry.

Laser welding machines achieve high density during pump impeller welding. Continuous agitation of the molten pool during welding facilitates gas escape, resulting in inherently porosity-free, fully penetrated welds. The high cooling rate post-welding promotes microstructural refinement, yielding welds with superior strength, toughness, and overall performance. The high-temperature heat source and full absorption of non-metallic components produce a purifying effect, reducing impurity content and altering the size and distribution of inclusions within the molten pool. The absence of electrodes or filler wires during welding minimizes contamination in the melted zone, ensuring weld strength and toughness that are at least equivalent to, or even exceed, those of the base metal.

The equipment developed by Top Optics Laser employs laser welding technology for impellers, overcoming the shortcomings of traditional resistance welding. The front and rear cover plates of the impeller achieve nearly 100% line sealing with the blades. The smooth and precise flow channels minimize hydraulic losses, significantly ensuring high-efficiency pump operation and reducing customer operating costs.

◆ Non-contact welding ensures smooth surfaces and high weld strength;

◆ Stable output, minimal heat-affected zone, low deformation, and easy automation;

◆ Rigid structure ensures strength and machining space, featuring high integration, automation, and intelligence for efficient welding;

◆ Three-station operation accommodates welding of impellers and diffusers of various specifications;

◆ Efficient and reliable welding fixtures enable easy loading/unloading, precise positioning, and high yield rates;

◆ Real-time monitoring and user-friendly design of the operating system;

◆ Fully enclosed metal protective chamber ensures convenient and safe operation with zero environmental pollution.